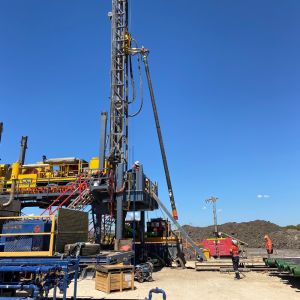

The Clear Cut RD20 XC Range III Drilling unit was manufactured by Atlas Copco USA (Now Epiroc) and delivered to Perth new in 2013 where the rig was utilised by a local contractor to drill some of the deepest water well and low heat geothermal bores in the Perth Basin to depths exceeding 1,000m. The rig was acquired by Clear Cut in January 2022 and will form a key part of the drilling, intervention and P&A capabilities of the Company moving forward.

There have been more than 300 of these rig designs manufactured with the majority in the USA where they are utilised by drilling contractors for shallow Oil & Gas Drilling or utilised exclusively for pre-setting top hole 20” and 13-3/8” casing for larger rigs. The “XC” feature denotes the “Extra Capabilities” which allows API drill pipe to be utilised with link tilt bails and hydraulic drill pipe elevators, a 3,000psi mud manifold and large 26” pass through rotary table with 17-1/2” API bowls are standard.

The RD20 is a solid choice for self propelled drive in drive out applications. The sub structure design utilises a ramp and jacking system that elevates the rig to provide a 4m substructure under clearance.

The rig substructure has been designed to allow augmentation with a hydraulic casing jack with 9″ or 11″ through bore. Loads can be transferred to the BOP and wellhead or contained within the substructure itself. The jack will provide a 1m stroke and allow safe overpull of a stuck tubular which can then be handed back to the rig for tripping out of hole or continually tripped out using the 1m stroke until pipe is free.

The rig is supplied with a string of 5” NC50 R2 drill pipe and pipe loader. The mud and circulation system can be adapted dependent on the type of project. The rig is configured with a 350psi / 1250cfm air compressor and air drilling manifold. The RD20XC is also compatible with a number of different CCI owned BOP configurations.