We provide the energy and resources sector with key solutions, services and value through our unique coalescence of people and innovative products across the full life cycle of Wells.

Our life-of-project execution approach assures optimised performance at every stage of your project’s lifecycle—with minimal downtime and cost overruns. All our equipment is supplied locally, significantly reducing mobilization / de-mobilization costs and equipment lead times.

Hydraulic Workover

CCI design, build and operate hydraulic work over units and platforms to the highest build specifications (API 4F) locally in Australia. Our units have up to 200 ton pulling capability, integrated pumping and rotary systems, tubing pick up and lay down options and remote control operations options. All our units are modular for ease of transport and provide remote access and fast rig up with multiple incorporated safety controls and data acquisition methods available.

- Dual 5ton Winches for pick up and lay down

- 15 Joints P/Hr

- 12 Hour Rig up / Rig Down Time

- Red Zone Free Capabilities (Remote Control Operations)

- 2-3/8” to 9-5/8”

- Withstand Cat 3 Cyclone forces whilst rigged up

- Designed to API-4F

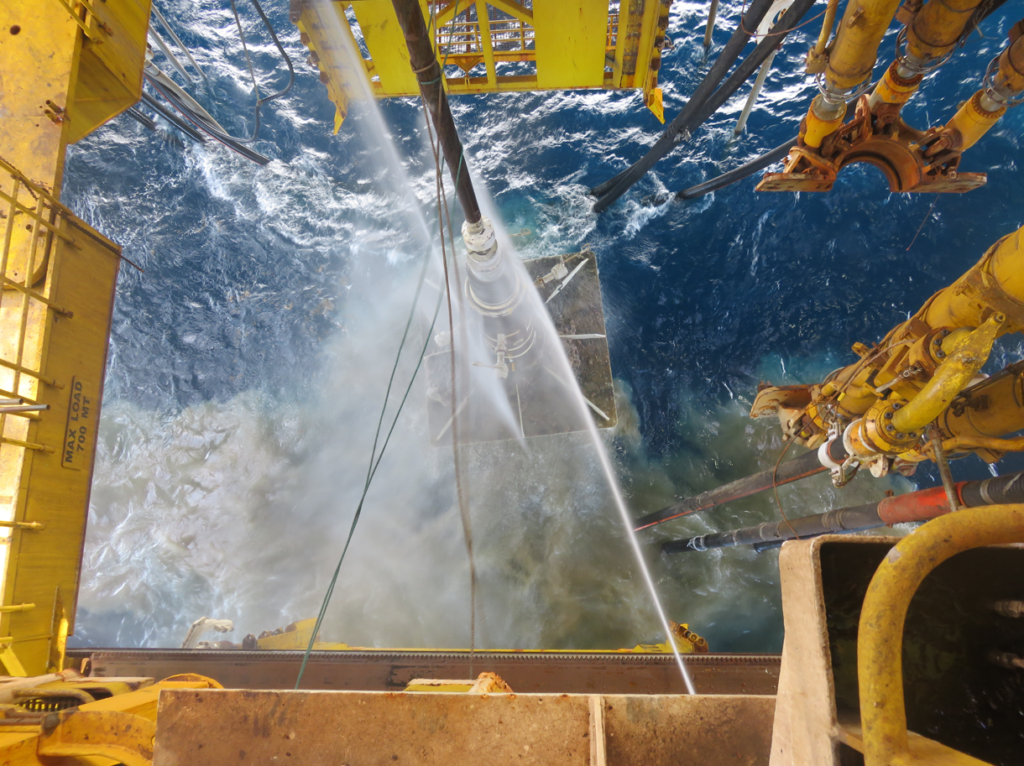

Coiled Tubing

Clear Cut interventions own and operate a Coil Tubing Unit suitable for both offshore and onshore projects. This locally available unit includes various auxiliary equipment options such as a portable data acquisition system.

- Our Injector Head can be run on a jacking frame

- Multiple runs offshore Western Australia under NOPSEMA approved Safety Cases

- Skid / Trailer mounted, DNV certified modular design. Separate skids include the following: Control Cabin & Power Pack, Injector Head & Gooseneck – 80,000lbs capacity, Jacking Frame, Hose Reel, 10k BOP, Stripper & Riser Frame with Test Stump, Nitrogen on demand package

- Low Speed / Pull – 59 ft/min @ 80,000 lbs

- High Speed / Pull – 210 ft/min @ 22,000 lbs

- Max Circulating Rate 110 GPM

- Skid mounted Control Cabin

- Hose Reel Skid

- Telescoping jacking Frame

- 7-1/16” 5K PCE skid & integrated test stump

- HS90 2-3/8” Tapered string (15,000 ft) – New

- QT900 2-3/8” String (12,600ft) – Used

Slickline

- Dual Drum ASEP (NOV) offshore Unit (6000lbs Pulling Capacity – wire limit)

- CS Fly line offshore unit (1250lbs pulling capacity – wire limit)

- Dual Ram 6-3/8” & 5-1/8” 10K BOP systems

- 5-3/4” Chemical Injection subs (10k)

- Well Control Panel & Grease injection capability for slickline / braided line

- Various Tool string inventory

drilling rig - rd20

The Clear Cut RD20 XC Range III Drilling unit was manufactured by Atlas Copco USA (Now Epiroc) and delivered to Perth new in 2013 where the rig was utilised by a local contractor to drill some of the deepest water well and low heat geothermal bores in the Perth Basin to depths exceeding 1,000m. The rig was acquired by Clear Cut in January 2022 and will form a key part of the drilling, intervention and P&A capabilities of the Company moving forward.

There have been more than 300 of these rig designs manufactured with the majority in the USA where they are utilised by drilling contractors for shallow Oil & Gas Drilling or utilised exclusively for pre-setting top hole 20” and 13-3/8” casing for larger rigs. The “XC” feature denotes the “Extra Capabilities” which allows API drill pipe to be utilised with link tilt bails and hydraulic drill pipe elevators, a 3,000psi mud manifold and large 26” pass through rotary table with 17-1/2” API bowls are standard.

The RD20 is a solid choice for self propelled drive in drive out applications. The sub structure design utilises a ramp and jacking system that elevates the rig to provide a 4m substructure under clearance.

The rig substructure has been designed to allow augmentation with a hydraulic casing jack with 9″ or 11″ through bore. Loads can be transferred to the BOP and wellhead or contained within the substructure itself. The jack will provide a 1m stroke and allow safe overpull of a stuck tubular which can then be handed back to the rig for tripping out of hole or continually tripped out using the 1m stroke until pipe is free.

The rig is supplied with a string of 5” NC50 R2 drill pipe and pipe loader. The mud and circulation system can be adapted dependent on the type of project. The rig is configured with a 350psi / 1250cfm air compressor and air drilling manifold. The RD20XC is also compatible with a number of different CCI owned BOP configurations.

DRILLING TOOLS

Through our partnership with NXG, we are focused on improving operational efficiency and the reduction of costs through smart design. We are fully committed to investing in game changing technologies and the development of ”next generation” drilling tools. Our dedicated engineering team will work with you to provide bespoke solutions to solve your operational challenges.

- Torque Reduction Sub

- Hole Cleaning Sub

- Hole Cleaning Heavy Weight

- Eccentric Drilling Reamer

- Drilling Reamer

- Multi-stage Drilling Reamer x2

- Sealed Bearing Roller Reamers

- Tri-Tornado Hole Openers

- Anti-vibration Tool

- Multi-activation Circulation Sub

- Multi-activation Piston (MAP)

FISHING TOOLS

CCI offer a wide range of fishing tools to remove wellbore obstructions safely and efficiently, greatly reducing the cost associated with wellbore problems. Tools include;

- Overshots

- Spears

- Pulling Tools

- Casing Cutters

- Mills

- Magnets

Pressure Control

CCI offers a large selection of Pressure Control technologies, including:

- 7 1/16” 5M BOP Stack consist of double ram and annular

- 13 5/8” 5M BOP Stack with single, double ram and annular

- 13 5/8” 10M BOP Stack with 2 double rams and annular

- 6 Station (3K PSI) Accumulator Unit to suit 10M & 5M BOP Stacks

- 3 Station (3K PSI) Accumulator Unit to suit 5M BOP Stacks

- HCR Manual and Gate Valves

- Slickline PCE

- 5 1/16” 10K PSI BOP

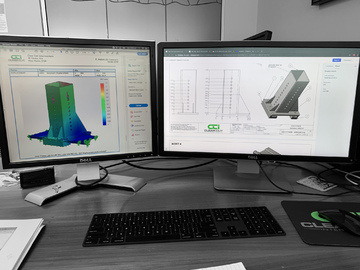

Engineering SERVICES

- Well Site Supervision on multiple offshore projects

- Desk Engineering (Various experience levels to cater for budgets and requirements)

- Landmark Modelling software

- Assistance with regulatory filing & management

- HAZ-ID’s & HSE reviews & Procedures

- Technical Well Programs

- Well Barrier Verification & Gap Analysis review

- Structural Engineering & Load Modelling